Where Recordkeeping Breaks Down: 3 Critical OSHA Logging Mistakes (And How to Fix Them)

Most recordkeeping failures don't happen when you're filling out the OSHA 300 Log. They happen before you ever touch the form: in the classification phase, when you're staring at an incident report and asking: Is this work-related? Does this require Days Away designation? Should this be logged as a privacy case?

Without documented decision logic, you're guessing. And inconsistent guessing creates audit vulnerabilities that can unravel years of safety work. The moment an OSHA inspector starts asking "How did you determine this case was work-related?" and you can't point to a defensible methodology, your entire recordkeeping system becomes suspect.

The Problem with "Good Intentions"

Most safety leaders approach OSHA recordkeeping with the right mindset: they want to be thorough, accurate, and compliant. But good intentions don't translate into defensible documentation.

The gap between "doing your best" and "having a documented process" is where programs break down.

Traditional recordkeeping training focuses on form completion: where to write the date, which boxes to check, how to calculate totals. But the real challenge isn't mechanical: it's decisional. When you're facing a gray area case at 3 PM on a Friday, you need more than regulatory knowledge. You need a documented decision tree that any safety professional can follow and defend.

The shift from compliance to culture starts here: moving from "I think this is right" to "This is how we determine work-relatedness, and here's the documentation to prove it."

Three Critical Classification Failures

1. Work-Relatedness Gray Areas

The Challenge: You have clear criteria for obvious cases: a finger laceration on the press brake is work-related. But what about the back strain that started during a shift and worsened at home? The bee sting in the company parking lot? The herniated disc that developed during the week but can't be pinpointed to a specific incident?

Why Programs Fail Here: Most companies rely on supervisor judgment calls without documented criteria. Site A might log the parking lot bee sting as work-related because it happened on company property. Site B might exclude it because the employee was walking to their personal vehicle. Both supervisors think they're being consistent, but they're applying different logic.

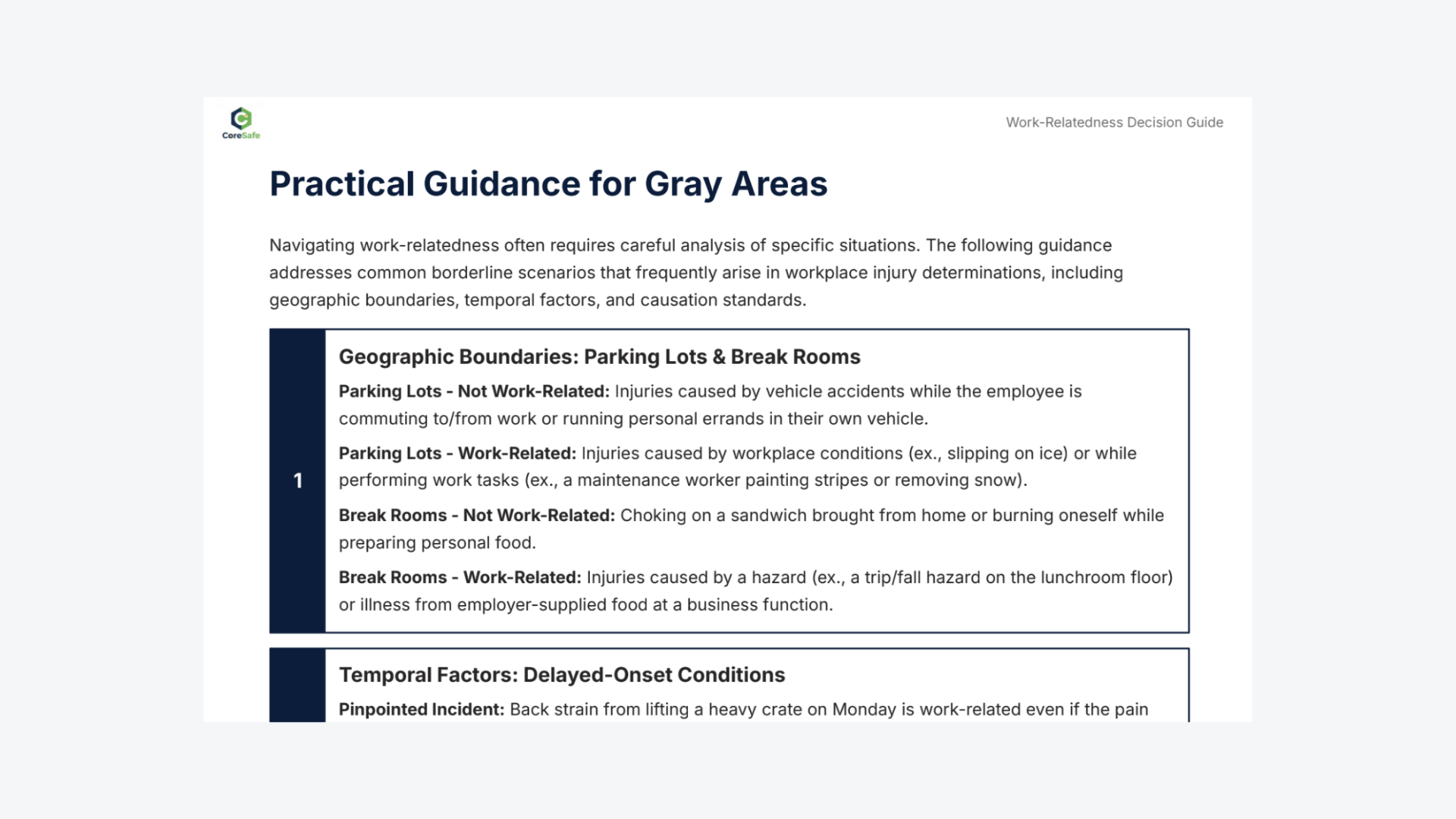

The Fix: Develop a work-relatedness decision matrix that addresses geographic boundaries, time parameters, and causation standards. Document specific scenarios:

Geographic boundaries: Define what constitutes the "work environment" (parking lots, break rooms, company shuttles)

Temporal factors: Establish time windows for delayed-onset conditions

Causation standards: Create criteria for distinguishing work aggravation of personal conditions versus work-caused injuries

Your matrix should reference OSHA's work-relatedness presumption (injuries in the work environment are presumed work-related unless an exception applies) while providing practical guidance for borderline cases.

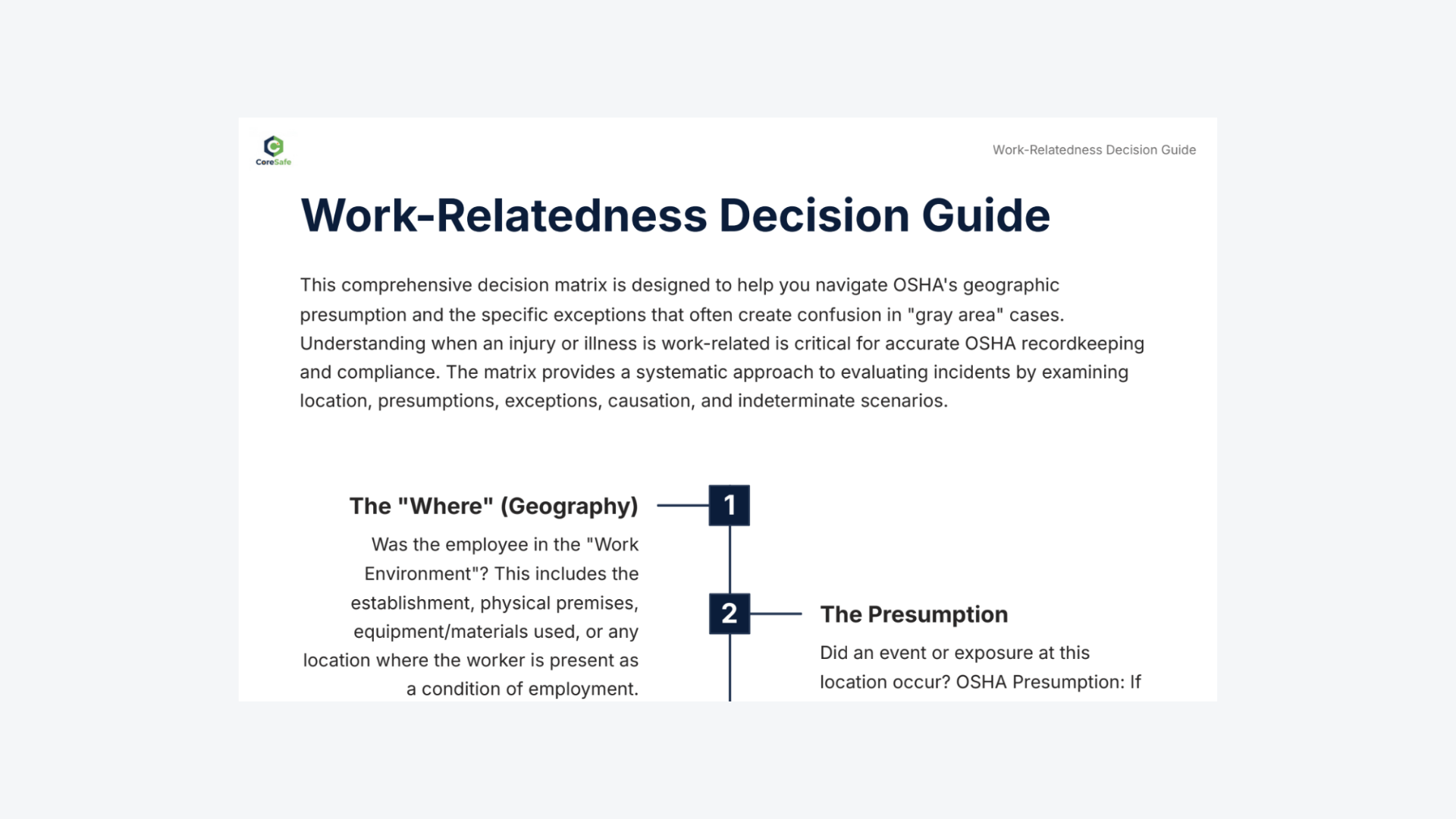

Figure 1: Geographic and Temporal Decision Criteria

The Work-Relatedness Decision Guide addresses the specific gray area scenarios discussed above—including parking lot injuries, break room incidents, and delayed-onset conditions. Each criterion includes work-related and non-work-related examples to eliminate guesswork. [View the complete guide in the OSHA 300 Recordkeeping Toolkit]

Figure 2: The OSHA Presumption Framework

This decision matrix walks you through OSHA's geographic presumption step-by-step, helping you determine whether an injury occurred in the work environment and whether any exceptions apply. The structured approach ensures consistent classification across all incidents and locations. [Access the full decision framework in the OSHA 300 Recordkeeping Toolkit]

2. Privacy Case Criteria

The Challenge: Section 1904.29 requires privacy protection for injuries involving intimate body parts, mental illness, HIV/AIDS, needlestick injuries, and medical removal. But most companies don't have a systematic process for identifying these cases or logging them correctly.

Why Programs Fail Here: Privacy cases require dual compliance: you must record the case on your OSHA 300 Log (it counts toward your totals) while protecting employee confidentiality. Many safety leaders either miss privacy cases entirely or handle them inconsistently across incidents.

The Fix: Create a privacy case identification checklist and separate logging procedure:

Identification triggers:

Injuries to intimate body parts (genitals, buttocks, breast of a female)

Mental illness cases (where the employee has voluntarily disclosed

HIV/AIDS, hepatitis, or tuberculosis

Needlestick or sharps injuries

Medical surveillance removals

NOTE: An employee may only request privacy for an illness, not an injury. If a strained back is classified as an injury, the employer must record the name unless it meets another privacy category.

Logging procedure:

Record "privacy case" in the employee name field (Column B)

Use a separate, confidential log for detailed case information

Ensure only authorized personnel access confidential details

Verify your state doesn't have additional privacy requirements

The key is having a documented process that shows deliberate consideration of privacy factors, not after-the-fact adjustments when someone raises concerns.

3. Multi-Site Standardization

The Challenge: If you're managing recordkeeping across multiple locations, inconsistent interpretation kills your defensibility. Site A interprets "Days Away" one way, Site B interprets it differently. Your consolidated 300A Summary becomes legally indefensible because the underlying data follows different standards.

Why Programs Fail Here: Most multi-site organizations provide basic OSHA training but don't standardize decision-making processes. Each location develops its own interpretation of gray areas, creating systematic inconsistencies that compound over time.

The Fix: Implement a centralized decision-making structure with documented protocols:

Standardization elements:

Centralized review: Require all gray area cases to be reviewed by a central safety team before classification

Decision documentation: Maintain a case precedent log that records how similar situations were classified and why

Regular calibration: Conduct quarterly reviews comparing classification decisions across sites

Training standardization: Use identical case studies and decision trees across all locations

Implementation process:

Create a "classification hotline" where site personnel can get real-time guidance on unclear cases

Develop a shared database of precedent decisions searchable by injury type, location factors, and work-relatedness elements

Establish monthly cross-site reviews to identify and correct classification drift

The goal isn't perfect uniformity: it's documented consistency. When an inspector asks why Site A and Site B classified similar cases differently, you need to show either that the cases were actually different or that you've corrected the inconsistency.

Moving Beyond Reactive Classification

The strongest recordkeeping systems don't just respond to incidents: they anticipate classification challenges. This means building decision-making frameworks before you need them, training personnel on edge cases before they occur, and documenting your logic before an inspector asks for it.

Your OSHA recordkeeping system reflects your safety culture's maturity. Organizations that guess their way through classification decisions send a clear message: safety is about compliance, not systematic improvement. Organizations that build defensible decision-making processes demonstrate that safety is a core operational discipline.

The question isn't whether you'll face gray area cases: you will. The question is whether you'll have the documented processes to handle them consistently and defensibly.

CoreSafe bridges the gap between compliance and culture by turning expert EHS knowledge into tools safety leaders can use with confidence. Whether you need guidance on recordkeeping or a full program structure, join our list here: